How To Repair Driveway Expansion Joints

Expansion Articulation Article of clothing and Damage

An expansion joint is commonly located on structures such equally bridges, highways and sidewalks. An expansion articulation is a mid-structure separation designed to absorb vibration, join objects, or allow motility. In structures, expansion joints can aid absorb the expansion and contraction of concrete slabs every bit a effect of temperature changes. Without expansion joints, the concrete can crack or distort. Notwithstanding, expansion joints on their ain are susceptible to failure. A major upshot is incompressible materials that lock the joints and create stresses that may cause concrete spalling or shattering. As a result, seals are ofttimes installed in expansion joints to forestall incompressible debris from entering the joint. Ii types of common seals are strip seals and compression seals.

Conventional Expansion Articulation Seals

Strip seals are flexible neoprene membranes adhered to the joint walls. They adhere well and prevent water ingress, but the seals can tear and disjoin under traffic if incompressible debris settles on peak. Pinch seals are neoprene or cellular seals in the form of a series of webs that provide outward pressure against joint walls to hold the seal in place. They are fix for use out of manufacturing, significant no mixing or curing is necessary. The seals need to be correctly sized to maintain the pressure against the walls, just the seal can still disjoin with the loss of elasticity over time.

Why Do Expansion Joints Fail?

Seals usually fail due to adhesion loss and cohesion loss. Adhesion loss is axiomatic when detachment of the seal from joint walls occurs. Adhesion loss is the loss of bond between the sealant and joint walls. Cohesion loss is axiomatic when a tear on or in the seal occurs. Cohesion loss is the loss of internal bail in the sealant.

How to fix expansion joints using the Belzona Solution

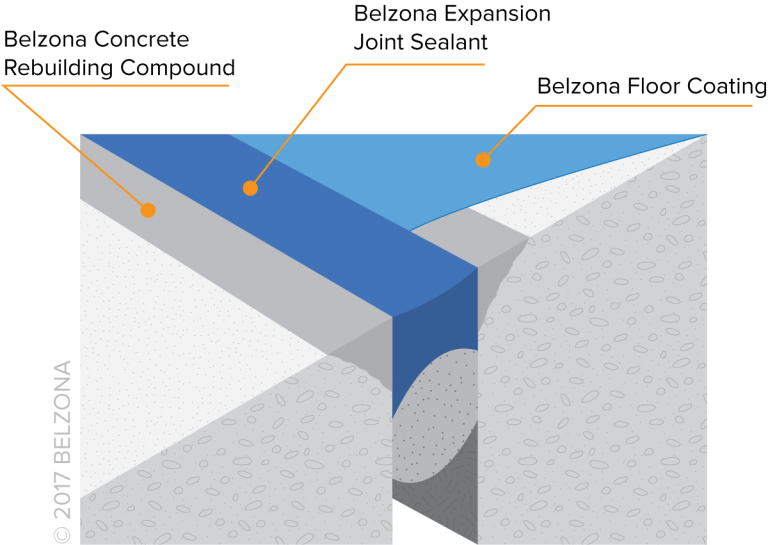

Conventional expansion joint seals accept their ain individual disadvantages and common failures. Belzona provides polyurethane sealants that protect expansion joints from incompressible debris while offer advantageous mechanical properties including high movement capability, loftier elastic recovery, and high abrasion resistance. In addition, Belzona polyurethane sealants comprise low odours and attach well to a range of substrates.

In our previous blog postal service "In Activity: Repairing Failed Expansion Joints in Healthcare", nosotros introduced an expansion articulation repair method chosen "Smooth Ride", mostly applicable to hospitals. In this web log post, nosotros demonstrate an expansion joint repair that can apply to any manufacture and whatever type of concrete joint.

Video: How to Fix a Failing Expansion Articulation with Belzona

For this repair, nosotros used:

- Belzona 4111 (Magma-Quartz) and a wooden batten to reform the nosings of the joint

- Belzona 2221 (MP Fluid Elastomer) and a backer road to create a new joint sealant

- Belzona 5231 (SG Laminate) to provide protection of the expansion joint and an artful expect

Additionally, we utilized Belzona 9111 (Cleaner/Degreaser) to clean the substrate, Belzona 9411 (Release Agent) to exist applied to the wooden crossbar, a handheld grinder and a pole sander to prepare the substrate, and a mixer for preparing Belzona 4111.

Stride-by-step instructions of expansion articulation repair

- Remove all existing cloth

Using a grinder with a round disc, remove all existing material and vee out the edges of the nosings.

- Remove all debris

Vacuum all the debris and grit.

- Roughen the surface

Abrade the edges and the surface with a pole sander.

- Make clean the surface

Thoroughly clean the surface with a cleaner/degreaser.

- Condition the Repair Surface

Thoroughly mix Belzona 4911 (Magma TX Conditioner) and brush it over the entire repair expanse.

- Insert wooden batten

Apply Belzona 9411 (Release Amanuensis) onto the wooden crossbar and position it in the joint.

- Mix Belzona 4111

Thoroughly mix Belzona 4151 Base and Solidifier until a homogeneous mix is accomplished. Slowly add Belzona 4111 Aggregate into the mix until the desired consistency is obtained.

- Trowel mixed Belzona 4111

Trowel mixed Belzona 4111 upwardly to the former to rebuild the expansion joint nosings. Make sure to fill up in all the empty spaces with the mixed product.

- Press Down Firmly

Pack Belzona product down firmly to avert air pockets formation.

- Remove the batten

In one case the Belzona product has cured, carefully remove the wooden quondam from the joint.

- Insert capitalist rod

Insert pre-measured foam backer rod into the articulation.

- Condition the Joint

Using Belzona 2911, condition the internal parts of the joint.

- Fill the joint

Cascade mixed Belzona 2221 to fill the joint.

- Smooth Out

Smooth out the surface, leaving it slightly concave.

- Mix Belzona 5231

Thoroughly mix Belzona 5231 Base and Solidifier until a uniform color is achieved.

- Apply mixed Belzona 5231

Using a conventional paint roller, utilise mixed Belzona 5231 over the expansion joint repair area.

- Application Complete

Remove all record masking the joint and the repair surface area. The application is now consummate!

Belzona'southward epoxy solutions can exist used to repair failing expansion joints. Belzona also offer solutions to an extensive range of applied science problems and repair situations.

Interested in purchasing Belzona's epoxy-based composites?

Source: https://blog.belzona.com/expansion-joint-repair/

Posted by: hendricksthemage.blogspot.com

0 Response to "How To Repair Driveway Expansion Joints"

Post a Comment